|

Drum unit

replacement.

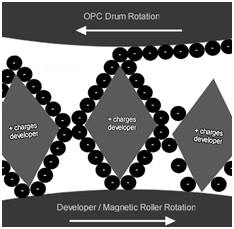

The drum unit contains Developer, Drum & Charge rollers.

Developer is rugby ball shaped carbon granules of a

predetermined size. Toner is added to the developer mix from the

toner cartridge, toner being negatively charged it is attracted

to the positively charged Developer granules.

Magnetic Brush / Development Roller

The developer and toner mix is agitated within the drum unit

where the developer being ferrite based it is attracted to the

Magnetic Development Roller, the Doctor Blade / Developer blade

limits the amount of Developer on the Development Roller.

Monitoring

the Toner / Developer mix level Monitoring

the Toner / Developer mix level

During this stage of the process the machine senses whether

there is enough toner in the mix and adds more if necessary.

This is done by inducing a charge in a coil of wire, when a

magnetic developer is rubbed against a coil it induces a

electrical charge in the coil. If there was no toner in the

developer mix then the developer granules would be closely

packed together on the development roller and would induce a

high charge. When toner particles are present in the mix the

developer granules are forced apart and a lower charge is

developed, this is how the machine maintains the correct toner

levels. As toner is transferred to the drum to form the image

the toner sensor voltage increases and the toner motor turns on

to add more toner until the sensor reaches its optimal value.

Why

do I need to change it? Why

do I need to change it?

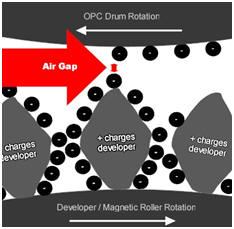

During the life of a drum unit the constant agitation of the

developer wears the granules turning them from diamond shapes to

rugby ball shapes. This then creates an air gap between the mix

and the toner sensor, because there is a gap a lower charged is

induced in the toner sensor coil which the machine interprets as

a high toner concentration therefore toner is not replenished as

required, the result is wishy washy solids, this effect will

intensify as wear continues. You will also find that the machine

starts to soot up with spilt toner that has not been transferred

to the drum properly.

OPC Drum Surface

The photo-conductor drum is a light sensitive coating on the

drum surface, this surface gradually gets worn by paper passing

under it, as it wears its sensitivity reduces and so it attracts

less toner, this compounds the developer problem.

|

New drum is just like a sharp pencil, sharp

lines, strong colours. |

|

|

|

Old drum is just like a blunt pencil, fuzzy

lines, weak colours. |

|

|

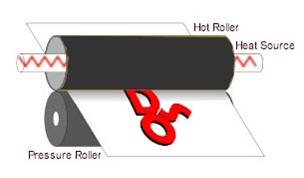

Fuser

Unit Laser

printers fix the toner onto the paper using heat and pressure

(Fuser Unit). The system employs two rollers the top roller

(heat roller) is a hollow aluminium roller coated in Teflon (the

roller is coated in Teflon to stop toner sticking to it).

Through the centre of the heat roller is a tungsten halogen

heater lamp (similar to a cooker) the lamp heats the surface of

the heat roller to approx 200 degrees. The fuser unit monitors

the temperature via a thermistor and turns on and off the heater

lamp. The lower roller (Pressure Roller) is rubber and is

constantly pressing against the heat roller. Fuser

Unit Laser

printers fix the toner onto the paper using heat and pressure

(Fuser Unit). The system employs two rollers the top roller

(heat roller) is a hollow aluminium roller coated in Teflon (the

roller is coated in Teflon to stop toner sticking to it).

Through the centre of the heat roller is a tungsten halogen

heater lamp (similar to a cooker) the lamp heats the surface of

the heat roller to approx 200 degrees. The fuser unit monitors

the temperature via a thermistor and turns on and off the heater

lamp. The lower roller (Pressure Roller) is rubber and is

constantly pressing against the heat roller.

A

bit about paper Laser

printer / copier paper has a 5% moisture content, this is why

the wrapper is coated in wax to stop moisture penetrating, as

soon as a ream of paper is opened it will absorb moisture until

equals the atmosphere (which can be 25 – 30%) A

bit about paper Laser

printer / copier paper has a 5% moisture content, this is why

the wrapper is coated in wax to stop moisture penetrating, as

soon as a ream of paper is opened it will absorb moisture until

equals the atmosphere (which can be 25 – 30%)

Photocopying or printing on paper with a high moisture content The

hot roller runs at a slightly higher temperature then the lower

pressure roller, so the top side of the paper nearest the heater

roller will get hotter causing it to curl due to shrinkage. Also

the moisture absorption is not constant so shrinkage occurs at

different rates causing a corrugated effect. This is not cause a

problem on single sided copies. But if you try and print or copy

double sided, you will have several issues, jamming, creasing

and print rubbing off.

· Jamming

– because the paper does not enter the fuser unit straight.

· Creasing

– because the pressure roller will try to crush the curled

corrugated paper flat.

· Print

Rubbing Off – Print will rub off because the high moisture

content has stopped the paper reaching 179 degrees, the fusing

temperature of toner.

Example I

was asked to repair a copier that appeared to be reducing an

image on the second side. The image had a square border 1cm from

the edge of the paper, when you held the double sided image up

to the light it was obvious that the second side was 3mm smaller

then the first side. A lot of head scratching and checking was

done. Finally I held a copied sheet up against an un copied

sheet of A3 paper the copied sheet had shrunk by 3mm during the

copy process. Because toner is laid onto the paper prior to

fusing the first side was correct, during fusing of the image on

to the first side of the paper had shrunk.

Moral of

the story If

you want to a reliable machine ensure your paper is dry.

For the best results make sure the paper is recommended for

double sided copying. If the paper has an arrow on the end the

packet it usually means single sided use, it may well double

side but you may have problems. When you open the paper, open

the reams carefully from one end, any paper left in the packet

can be protected by folding the end of the packet back over and

putting the paper back in the box. This is especially true of A3

paper that may hang around for months before being used.

Toners

Compatible ! why Oki machines work well with our compatible

toners Toners

Compatible ! why Oki machines work well with our compatible

toners

Oki machines are one of the few manufacturers whose toner

cartridges only contain toner. The Drum unit that is replaced

every 3 toners contains the developer, cleaning blade and drum.

The Oki toner supply system also suits compatibles due to it

being gravity fed system. A roller in the base of the toner

cartridge feeds toner into the drum unit as and when required.

We have been supplying compatible Oki toners for 4 years with no

detrimental effects. See our total

cost of ownership page

to see how you can save 33% on your running costs.

Toner Compatible? should I use them!

People assume a toner cartridge just contains toner, this is

only true in a few cases. Most toner cartridges contain three

components.

-

Toner, the powder that is

fused on to the paper to form the image

-

Developer, a graphite based powder that

regulates the amount of toner reaching the paper (similar to

the nib of a fountain pen).

-

Drum, PCU, Photoconductor, a light sensitive

drum.

The reason compatible toners vary in price and quality so much

is down to the cartridge?

-

Has it just been refilled

with toner.

-

Has it been refilled and the Drum and

cleaning blade replaced.

-

Has been remanufactured with new toner,

drum, cleaning blade and Developer.

The only way to know is to use the cartridges and find out what

happens!

The cartridges we sell are remanufactured cartridges, that we

will warrant is being fit for purpose, NO compatible

cartridge will work as well as an original.

If you

would like to book a service call ring 01293 537827 or email sales@digital-office-solutions.co.uk

| Local

printer sales, supplier new, refurbished, reconditioned

and used Crawley, Horley and Gatwick |

|

DOS are a local printer

repair specialist, our experienced mobile technicians

offer an on site printer installation

Printer sales, supplier new, refurbished, reconditioned

and used Crawley, Horley and Gatwick, Digital Office

Solutions offer printers, laser printers, wide format

printers and plotters from Brother, Canon, Epson, HP

Hewlett Packard, Konica Minolta, Kyocera Mita, Oki,

Ricoh and Samsung in Crawley, Horley and Gatwick, West

Sussex & Surrey area. |

|

Printer sales, supplier new, refurbished, reconditioned

and used Crawley, Horley and Gatwick, Digital Office

Solutions offer printers, laser printers, wide format

printers and plotters from Brother, Canon, Epson, HP

Hewlett Packard, Konica Minolta, Kyocera Mita, Oki,

Ricoh and Samsung sales, supplier new, refurbished,

reconditioned and used Crawley, Horley and Gatwick in

Crawley, Horley and Gatwick, West Sussex & Surrey area. |

|